Seal Test / Sealing Test distributing|seal integrity test pdf : purchasers Seal Peel Test - ASTM F88. Determines the strength of the seal at a specific place on the package. 2 Seals •Manufacturer’s . seals can occur with improper sealing parameters. For example: insufficient heat, pressure, or too short of dwell time. Narrow Seals. Tray misalignment . Internal creep due to tray webVídeos pornô mais relevantes para: Luziane Baierle Onlyfans - Melhores xvideos grátis online com famosas nuas que vazou na net do Onlyfans e Privacy massage black

{plog:ftitle_list}

WEBBest 2x2 Gaming Slot Games The company's portfolio includes slots on various topics .

Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently .Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. These tests measure the force required to separate .November 10, 2021. 3 Min Read. Enhanced package seal integrity is once again top-of-mind due to recent supply and demand challenges that include these .

Seal Peel Test - ASTM F88. Determines the strength of the seal at a specific place on the package. 2 Seals •Manufacturer’s . seals can occur with improper sealing parameters. For example: insufficient heat, pressure, or too short of dwell time. Narrow Seals. Tray misalignment . Internal creep due to trayWhether in-house testing or field trials, we are able to reproduce ideal and worst-case operating conditions, recording seal integrity, as well as monitoring pressure, speed, temperature, and a number of other performance factors. .We not only offer new seals, but we can also recondition existing seals. We stock Armstrong Circulators and Parts, Gaskets, Bearings, O-Rings and Kits, Capacitors, Shaft Sleeves, Locking Collars, Packing and more. We also carry U.S. Seal, .

Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs toCO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

CLASSIC 513 Gradient Heat Seal Tester is professionally designed for the determination of heatsealability of plastic films, composite films, coated paper, and other sealing films under certain sealing speed, pressure and 5 different temperatures.Der Peel-Test ist neben dem Seal-Check, dem Tintentest und der Siegelnahtfestigkeitsprüfung ein gängiges Verfahren zur Beurteilung der Siegelnaht-Qualität eines Siegelgerätes. Die Durchführung des Peel-Tests ermöglicht es, fehlerhafte Siegelungen rechtzeitig zu erkennen und zu beheben. Denn nur eine korrekt verschlossene Verpackung .The seal is tested at a rate of 200 mm/min ±10 mm/min and the maximum force recorded. The computer-controlled test system offered Rocket Medical full programming capability. The system displays the maximum force achieved during the test, as well as the average maximum force incurred over a number of tests.

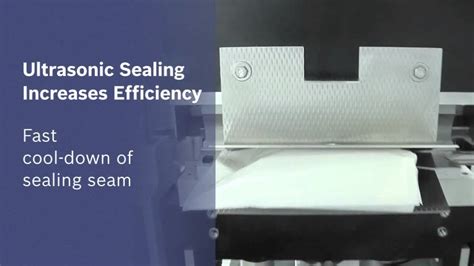

ultrasonic seal testing

There has been good correlation between results obtained with the AD-3050 seal test and those obtained through water immersion testing. Features. Fast determination of sealing integrity; Multiple test fixtures; Easy load and release of test samples; Timer adjustable from 8 – 120 seconds (only with integrated AD-3050 Seal Test Equipment timer .sealing cycle but prior to the temperature of the seal reaching ambient. Refer to Test Methods F1921. 3.1.6 seal initiation temperature, n—on a heat seal curve, the sealing temperature/dwell pressure at which heat seal strength first begins to trend upward from zero heat seal strength. 3.1.7 sealing interface, n—the interface of the two webC660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11067, ASTM F1140 & ASTM F2054. Request a Quote View MoreLeakdown testing is an effective and inexpensive way to evaluate engine cylinder sealing and pinpoint issues. Skip to content +1 (800) 772-2678 or +1 (269) 463-4113; . and head gaskets. Whereas a compression test measures how much pressure is generated inside a given cylinder while cycling the starter, a leakdown test measures the amount of .

Product Description. Pouch Seal Integrity Test : Designed to test the integrity of seals on either paper/poly or Tyvek® /poly packaging material, the Pouch Seal Integrity Test checks for an intact seal, punctures, tears and open seals of heat seal and self-seal pouches. The Pouch Seal Integrity Test is packed in an aluminum package to protect the ink against .Twist ’N Seal® Pipe Sealing Plug Product Description and Features. Securely block off a variety of pipes from the inside with the Test-Tite Twist ‘N Seal Pipe Seal Kit. Quick and easy to use, this pipe seal kit allows you to install a temporary sealing plug inside DWV (drain, waste, and vent) pipe, stopping the water flow while you solder .

Various criteria such as the force required and the chamfering of the sealed seam are evaluated. Alongside the seal check, the ink test and the seal seam strength test, the peel test is a common method for assessing the seal seam quality of a sealing device. Performing the peel test makes it possible to detect and rectify faulty seals in good time.

Here both, individual components and complete sealing systems are tested according to customer-specific requirements. Using SKF SEALJET Systems, which is also available for SKF distributors, seal prototypes can be created in-house in almost no time at all, which offers an extreme flexibility for internal test rig investigations.should perform a Compatibility test on the two materials supplied to verify that they are compatible. South Dakota DOT Test Procedure SD 322 Method of Test for Determining Compatibility of Cover Aggregates should be used to determine the compatibility of the two materials. The fifth step is the Construction of the chip seal.package inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETO

The test procedure may be used to test seals of alternate size and design or using alternative media but such deviations shall be detailed separately on the report form and the results shall not be used to determine the minimum operating temperature of seals .Test open or plain end pipe and tube by sealing on pipe OD. Patented self-gripping, self-sealing design, and reliable dual seal mechanism provides unparalleled speed and safety in hydrotesting. Durable construction; corrosion resistant aluminum body and hardened grippers. Test Pressure Up to 5000 PsiG (345 BarG)

6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments.To test the integrity of mechanical seals fitted with a secondary containment seal. This document is general in nature and does not refer to site specific requirements. The site has the responsibility for ensuring that tests are carried out.

seal strength testing

Except the throttle valve, all the valves are supposed to have certain closing sealing performance, so the valves must go through the sealing test before they leave the factories. The valves with the back seats also need to undergo the back seat sealing test. The sealing test for the valve is usually carried out at the room temperature and under the nominal pressure.Our prices are competitive and because we are one of the largest stocking distributors of Flowserve Pac-Seal® mechanical seals in the world, we are able to carry the many types of mechanical seals you might need. We also carry U.S. Seal Mfg.®, Advanced Sealing International® and Utex® products.The Sepha PakScan is a non-destructive test method. The machine performs a dry seal integrity test enabling manufactures to recover packs that have passed the leak test and return them to the production line. The system can identify gross holes, leaks and weak seals down to 10μm* in up to 10 packs simultaneously within 30 seconds.Assemble the parts, then conduct opening and closing first, repeat three times, it's qualified when the opening and closing is flexible without jamming; then the shell test, the test pressure is 1.5 times the nominal pressure, no leakage is qualified; and then seal test, the test pressure is 1.1 times the nominal pressure, reach the national GB/T13927 standard is the qualified.

CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

wet bottle test

what are tester bottles

Resultado da Publicidade. Ah! No Reclame AQUI, empresas ruins, não recomendadas e em análise não são anunciadas. Caso veja alguma, não deixe de nos avisar: [email protected]. Saiba se a empresa Firefly Games é .

Seal Test / Sealing Test distributing|seal integrity test pdf